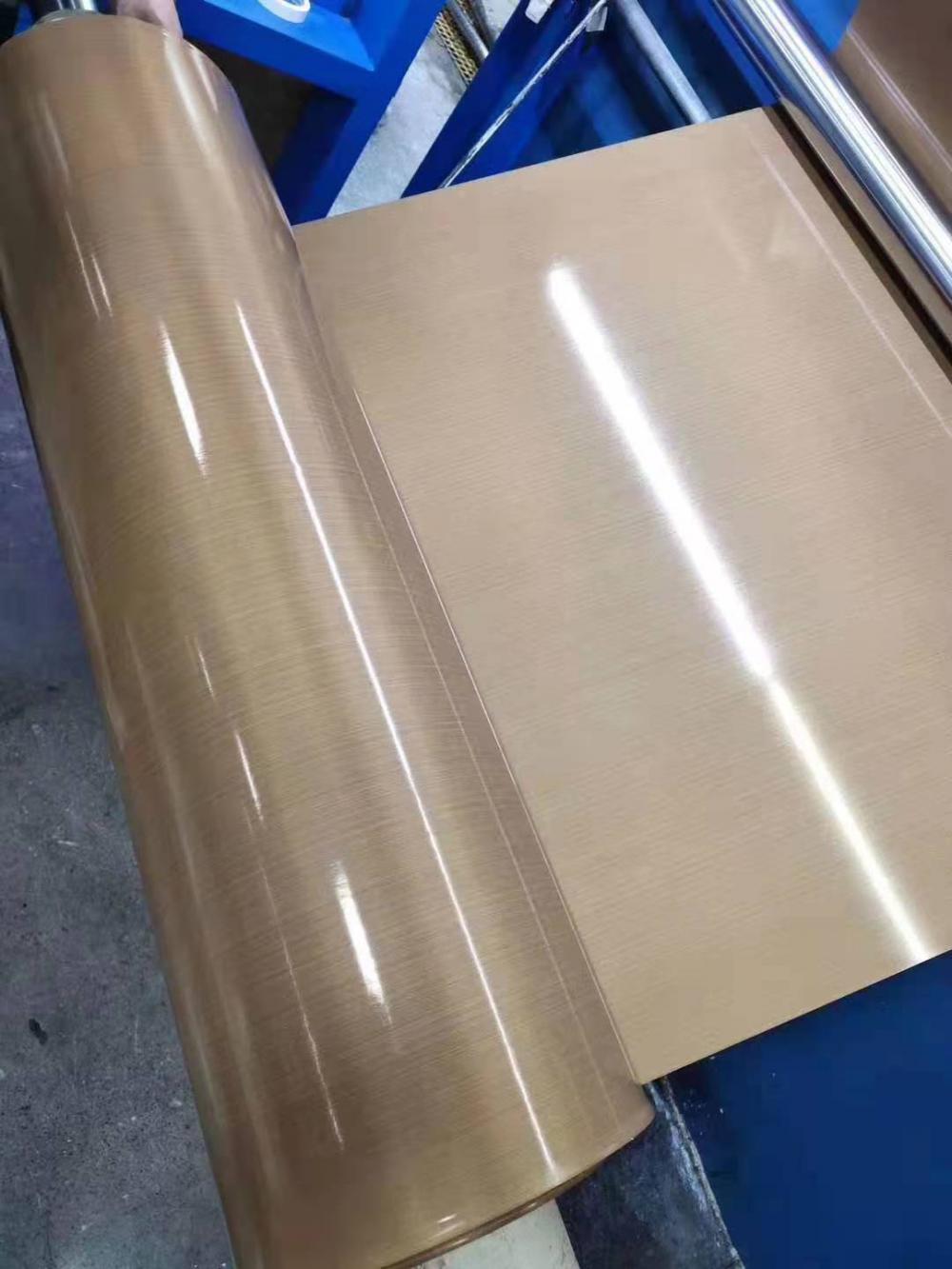

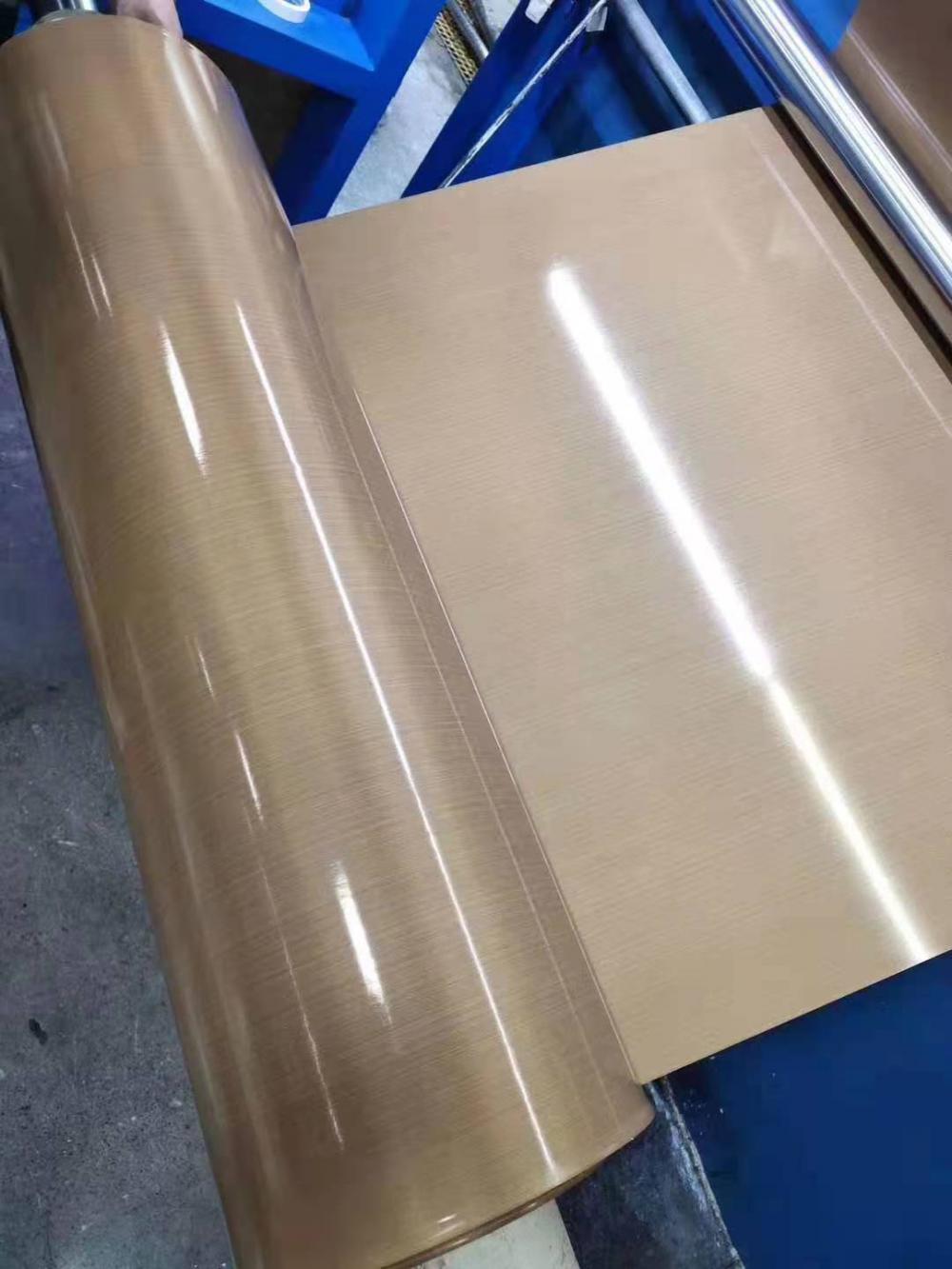

brown high temperature resistance PTFE coated fiber cloth is also called PTFE coated Fiberglass Fabric

We use best imported Fiberglass as the weaving material to plain knit or specially knit into superior fiberglass basic cloth, coat it with fine PTFE resin then make it into various of PTFE high temperature resistance cloth in different thickness and widths.

specifications of PTFE Fabric:

| Item No | Color | Thickness | Max width | weight | Tensile strength | Temperature |

| Q3008AJ | borwn | 0.08mm | 1250mm | 165g/m² | 130/120N/cm | -140 to 360℃ |

| Q3008BJ | black | 0.08mm | 1250mm | 170 g/m² | 130/120N/cm | -140 to 360℃ |

| Q3008Y | black | 0.08mm | 1250mm | 185 g/m² | 130/120N/cm | -140 to 360℃ |

| Q3013AJ | brown | 0.13mm | 1250mm | 260 g/m² | 220/190N/cm | -140 to 360℃ |

| Q3013BJ | black | 0.13mm | 1250mm | 275 g/m² | 220/190N/cm | -140 to 360℃ |

| Q3013Y | black | 0.13mm | 1250mm | 290 g/m² | 220/190N/cm | -140 to 360℃ |

| Q3018AJ | brown | 0.18mm | 1250mm | 395 g/m² | 330/250N/cm | -140 to 360℃ |

| Q3018BJ | black | 0.18mm | 1250mm | 415 g/m² | 330/250N/cm | -140 to 360℃ |

| Q3025AJ | brown | 0.25mm | 2800mm | 490 g/m² | 410/330N/cm | -140 to 360℃ |

| Q3025BJ | black | 0.25mm | 2800mm | 510 g/m² | 410/330N/cm | -140 to 360℃ |

| Q3035AJ | brown | 0.35mm | 3200mm | <660 g/m² | 560/445N/cm | -140 to 360℃ |

| Q3035BJ | black | 0.35mm | 3200mm | 680 g/m² | 560/445N/cm | -140 to 360℃ |

| Q3040AJ | brown | 0.40mm | 3500mm | 780 g/m² | 820/500N/cm | -140 to 360℃ |

| Q3040BJ | black | 0.40mm | 3500mm | 820 g/m² | 820/500N/cm | -140 to 360℃ |

| Q3065AJ | brown | 0.65mm | 4000mm | 1150 g/m² | 1080/750N/cm | -140 to 360℃ |

| Q3090AJ | brown | 0.90mm | 4000mm | 1550 g/m² | 1500/1250N/cm | -140 to 360℃ |

| Q3090BJ | black | 0.90mm | 4000mm | 1650 g/m² | 1500/1250N/cm | -140 to 360℃ |

PTFEcoate fiberglass fabric is made up of high-capability fiberglass which has steeped into PTFE. It is a new product with high capability and multiform function of complex material. Fiberglass fabric coated with PTFE has various good capability and it is widely used in aircraft industry, paper manufacture, food, environment protection, print and painting, costume, chemical, glass manufacture, medical, electronic, insulation, building (basic cloth of topping frame), sharpener slice, machinery, etc. Main capability and characteristics:

- It can be used under the temperature of - 196 ℃ to 360 ℃, which has the capability of weather resistant and age resistant. Under practical situation of high temperature of 250 ℃ for 200 days, not only the intensity will not decrease, the weight will not reduce; if put it under the high temperature of 350 ℃ for 120 hours, the weight only decreased by about 0.6%; under the situation of -180 ℃, it will not chap and keep the original pliability;

- Hardly to adhere any material; it is easy to wash away the blot or other dust such as resin, coating material, etc.

- Chemical corrosion resistant, it could resist acid, alkali, aqua fortvarious kinds of organic liquid corrosion;

- Low ratio of friction (0.05-0.1), it is the best choice of non-oil lubricator; Light piercing ratio is 6-13%;

- High capability of insulation (small permittivity: 2.6, the tangent is lower than 0.0025), ultraviolet resistance, static prog;

- Good dimension stability (the ratio of extending is lower than 0.5%), High intensity, good mechanical capability; Capability of medicament resistant and non-poison, almost to resisting all kinds of medicament; Fireproofing and flame resisting.

Applied range:

1. Internal gasket, cushion, covering fabric, conveyer belt which resisting viscidity; base on the different thickness, it could be used as conveyer belt, conglutinating belt, sealing belt of various kinds of drying machine;

2. welding of plastics, welding cloth for solder; plastic patch, membrane, belt of heat enveloping patch;

3. High insulation of electric: insulating belt of electric, septa, cushion, gasket. High frequency plank coated with copper;

4. heat resisting envelope, terrace base-material, enswathing of heat insulation;

5. micro wave gasket, oven gasket, food drying;

6. glue belt, shifting stamp tablecloth, blanket backing-glue belt, rubber vulcanize belt, etc;

7. fabric of heat-variable glue;

8. construction membranous material: sorts of ceiling of gymkhana, station ceiling, parasol, and sight ceiling;

9. binding of all sorts of petroleum and chemical pipeline to resist eroding, environmental sulfur separating of exhaust gas of electric factory;

10. bland compensator, rubbing material, slice of grinding wheel;

11. it could be made into static resisting fabric.

Note:

We could produce different kinds of fiberglass fabric coated with PTFE according to different application request, for example:

1. ordinary industry grade: the textile of this grade is with good capability of heat resistant, antisepsis, non-viscidity;

2. standard grade: it is made of import material, besides having the grate capability of antisepsis and heat resistant, the surface is more smoothly and it has better non-viscidity capability. It could be used in ordinary industry field, and has better predominance on being used as plastic module separating, and separating patch, gasket, separating module of some products.

3. food grade: the surface is smoothly, good capability of resisting viscidity, heat resisting, easy wash, and it is more safety to be used on food industry;

4. static resisting grade (fabric of static resisting): besides the capability of fiberglass fabric coated with PTFE by special process, it has the capability of resisting static which to satisfy the request of customers.

Main sorts and specifications:

Thickness: 0.06-1.0mm; Structure of basal fabric: plain, diagonal, satin, etc.

Width: 1000-4200mm;

Color: brown, white, black, black-argent;

Way of coating: double-faced coating, single-faced coating, ventilate coating, static resistant coating.